© Copyright Ricoh DTG 2024 All rights reserved

Introduction

This TD&R document is intended to aid RICOH DTG users how load Ricoh's new Type G2 white ink.

Previously White ink Cartridges for the Ri 2000 were:

342520 White 1 ink Cartridge RICOH type G1

342521 White 2 ink Cartridge RICOH type G1

342600 White 1 ink Cartridge (Hi Yield) RICOH type G1

342601 White 2 ink Cartridge (Hi Yield) RICOH type G1

The new improved ink cartridges are:

342836 White 1 ink Cartridge RICOH type G2

342837 White 2 ink Cartridge RICOH type G2

342812 White 1 ink Cartridge (Hi Yield) RICOH type G2

342813 White 2 ink Cartridge (Hi Yield) RICOH type G2

Needed for recommended flushing

QTY 1 342526 RICOH cleaning cart White 1 type G1 QTY 1 342527 RICOH cleaning cart White 2 type G1

Important note: Prior to changing from type G1 to type G2 white ink – confirm that the nozzle check is good. If there are many missing nozzles, the process of changing over to type G2 ink will not necessarily resolve any preexisting clogging or other issue: Please refer to this article on our knowledge base for tips on how to recover the nozzles https://ricohdtg.com/support/ri-1000-head-recovery-guide

Ricoh newest white ink technology sets a new standard for quality and performance. Ricoh White ink Type G2 has superior vibrancy and durability to environmental conditions.

Improvements

• Increase in vibrancy between prints

• Less settlement within cartridges and ink lines

• Improvement in nozzle jetting performance

• Improvements in durability to environmental conditions.

Loading White ink

When switching to the new Ricoh Type G2 ink there are a few things you need to consider when switching.

1. All cartridges must be switched at once . We can NOT have different white ink (Type G1 and G2) cartridges in the same machine. Print results will not be good and it may lead to nozzle loss. This means all white ink cartridges need to be matching.

2. Option 1 - It is recommended that you fully flush out the old type G1 white ink prior to loading the new type G2 white ink. – This will allow you to enjoy all the benefits of the new white ink right away. This means you will need Cleaning cartridges to flush the machine. The cleaning carts will need to be at least 50% full in order to complete the flush.

3. Option 2 - You can also skip the flushing process and just put in the new Type G2 white ink cartridges. This will require at least 5 strong cleans on all 2 white heads to be performed after inserting the new cartridges. This will not harm the machine, but you may notice nozzle loss and will have to flush the lines at that point anyway.

Flushing the printer for Option 1

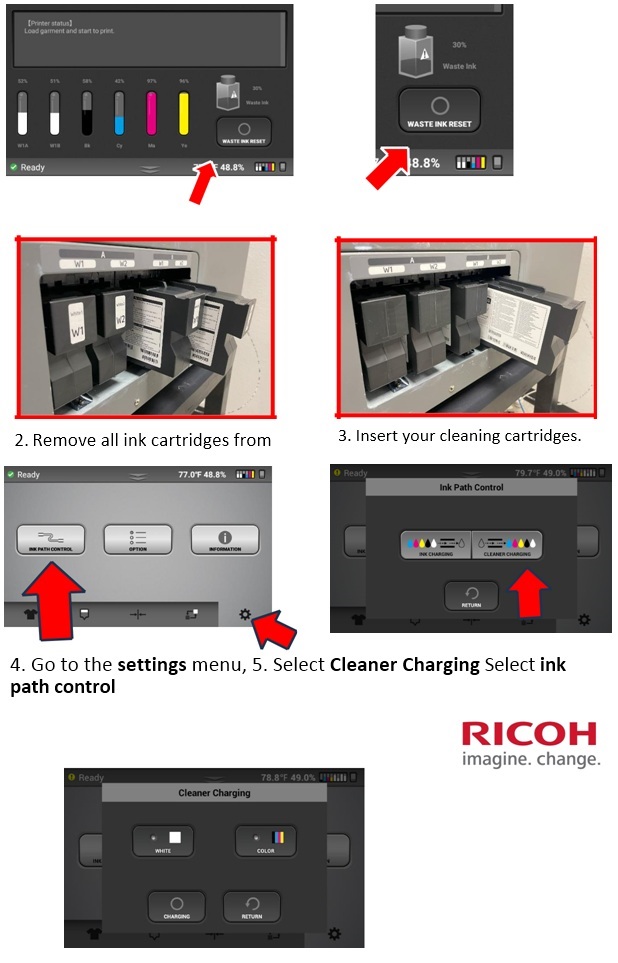

1. Check the level of the waste tank – if it is near full then you will need to empty it to prevent the flushing process from failing. In this case, make sure you empty your waste ink bottle and reset the counter.

6. Ri1000 and Ri1000x – You have the option to Flush all channels(CMYKWW) or flush the whites only (WW). You will be flushing the white channels only.

The flush process will take some time to complete.

7. The flush will clear out the Type G1 white ink in the lines and print carriage

8 Visual inspection

After the flush has been completed check your ink lines visually to make sure they have flushed out completely. The white lines should be fully transparent, we

do not want to see any white ink or “milky” cleaning fluid inside. See image below.

Ri 1000 and Ri1000x

Lines are flushed, CMYK lines will have color tint left on tube but the white should be translucent like the photo here.

Filling printer with White Type G2 ink

Shake white ink for 100 seconds

Before inserting the cartridges into the printer, we need to shake the cartridge for 100 seconds, 2 time per second (200 total shakes). This will mix the pigment back around and is an important step to avoid loading settled ink.

If you have flushed your printer, then refill with white ink as shown below.

Filling printer with RICOH Type G2 White ink

The fill process will take about 25 minutes to complete.

Once the fill has been completed. Print a nozzle check.. If the nozzle check is 100% or near 100% you have completed the ink switch. If there are a few missing nozzles, then perform head cleans as described in the manual.

Comments

Post a Comment